1.How long does it take for normal delivery?

The normal delivery time of our company depends on the customer’s purchase quantity and product technology. Welcome customers to consult.

2.Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

3.What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction

4.Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

5.How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

6.Can I get the catalyst quickly?

We have enough stock and strong production capacity to ship quickly, and we can deliver the goods to your warehouse by air. If you want to save the cost, we can also send the goods to your port or warehouse by sea.

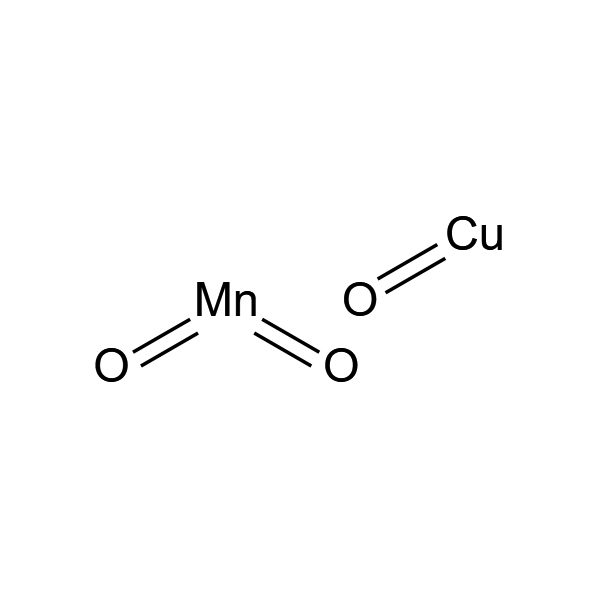

7.Can I choose to customize it?

Of course, we have mature production technology, comprehensive technical engineers and advanced manufacturing equipment. Just tell us your product requirements and we will find the best solution for you.

8.Can you provide samples?

We can provide you with samples and provide you with corresponding samples according to your product needs.